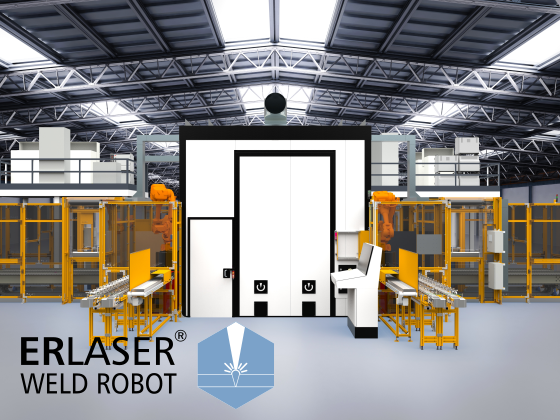

ERLASER® WELD ROBOT Shuttle

Compact welding system with shuttle systems - Low-warpage welding of sheet metal assemblies

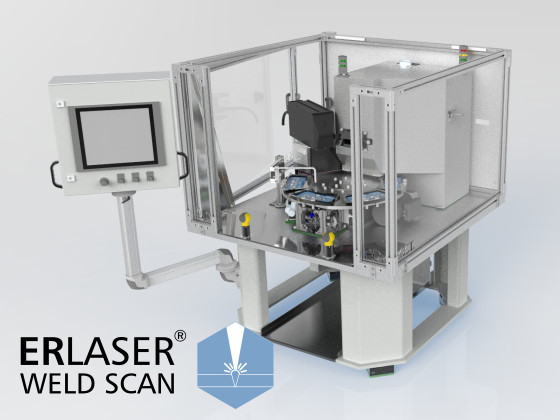

ERLASER® WELD SCAN Index

Variant-flexible rotary transfer machine with exchangeable workpiece nests for 2D scanner welding

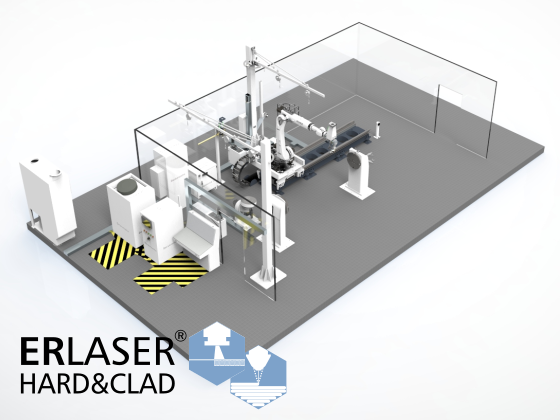

ERLASER® HARD+CLAD XL

Roboter gestützte Anlage zum Härten und Auftragsschweißen an Bauteilen mit großen Abmessungen.

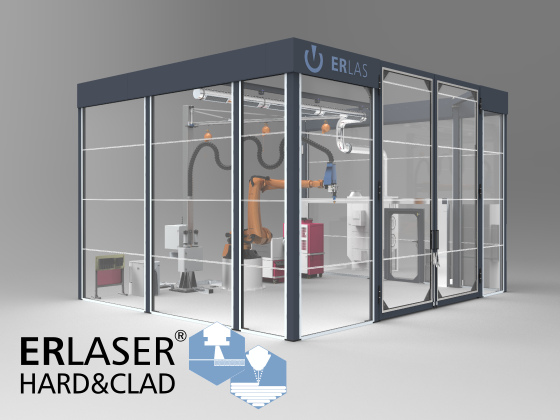

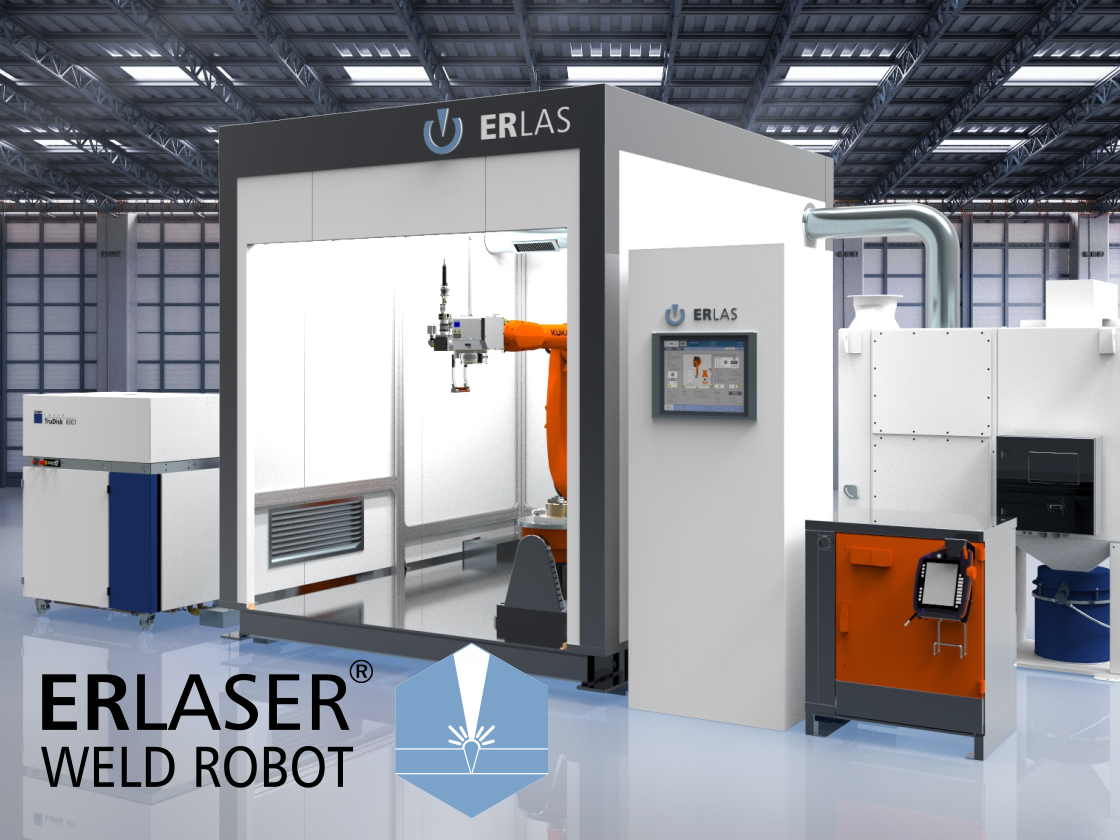

ERLASER® WELD ROBOT

Compact robot welding cell for prototype and small batch production with manual loading

ERHEAD VARIOSPOT 25

ERLAS präsentiert den ERHEAD VARIOSPOT 25. Das neue Multitalent mit vier Anwendungen vereint in einem Laser-Bearbeitungskopf.

Too many filters are selected.

English (EN)

English (EN)